Modern supply chains are becoming increasingly dependent on inland infrastructure to relieve pressure from congested ports and provide faster access to cargo. That’s where Inland Container Depot Software comes in — a powerful, all-in-one solution for managing container flows, customs procedures, and yard operations at dry ports, bonded terminals, and rail-linked inland depots. Whether you’re running a private ICD or a government-regulated facility, the right software platform can automate daily workflows, reduce dwell time, and enhance traceability across every container movement.

Introduction — What Is Inland Container Depot Software?

Inland Container Depot Software (ICD Software) is a specialized category of logistics management platforms designed for dry ports and inland logistics hubs. These depots act as extensions of maritime ports but are located away from coastal terminals, usually connected via rail or road corridors. As international trade volumes grow and seaports become saturated, inland depots serve a critical role in maintaining throughput efficiency and improving the last-mile connectivity of containerized freight.

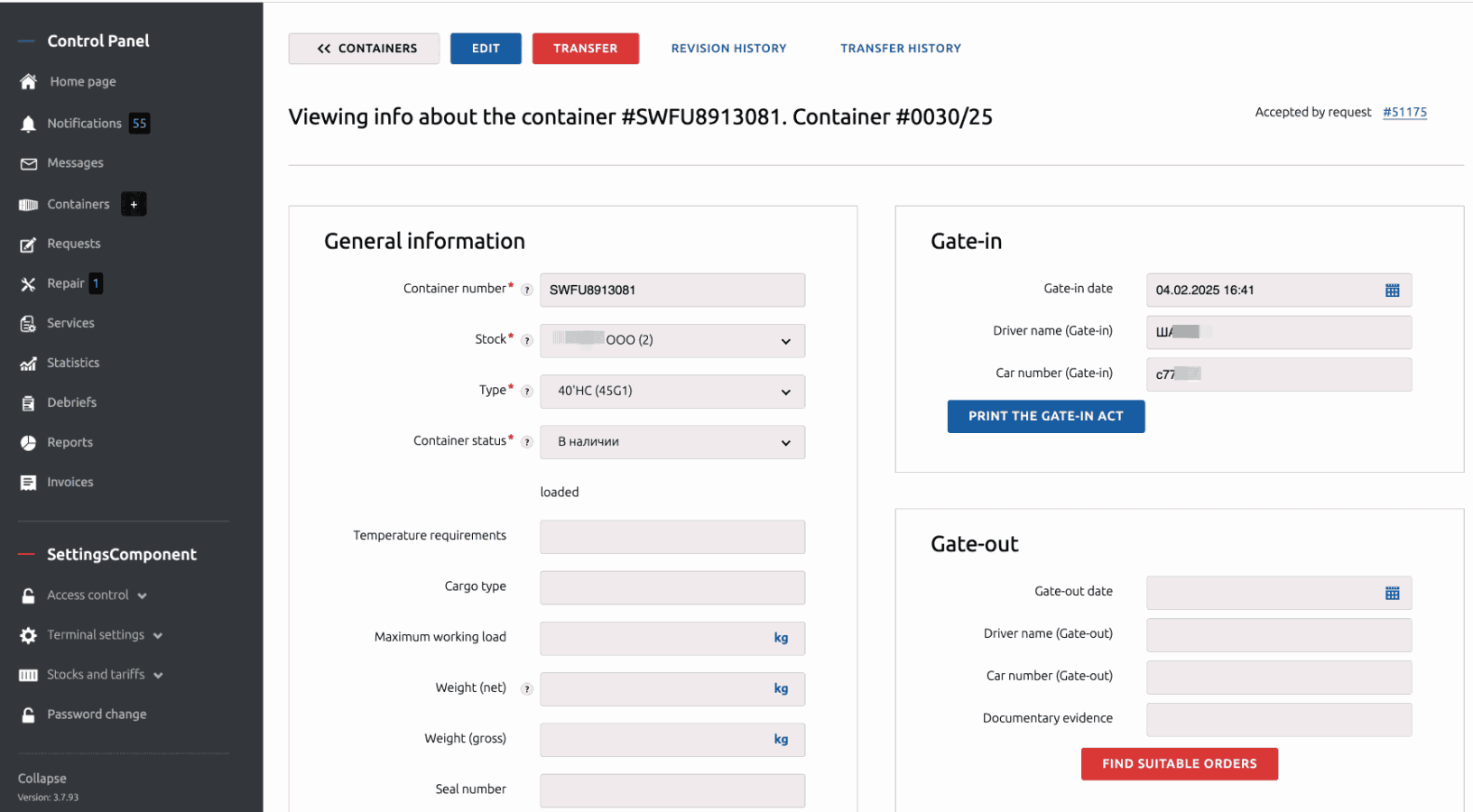

ICD Software provides the digital infrastructure needed to operate such facilities with precision. It integrates real-time container tracking, gate management, yard planning, customs compliance, and billing processes into a centralized control system. Moreover, it supports EDI messaging standards like CODECO and CUSCAR for communicating gate movements and customs status to shipping lines and authorities.

Unlike traditional WMS or TOS systems, inland depot software is tailored to the specific needs of inland hubs — where customs clearance, rail slot planning, and bonded cargo monitoring are as important as stacking efficiency.

Key Functions of ICD Terminals

An Inland Container Depot (ICD) functions as a full-service logistics facility that handles the reception, storage, customs clearance, and onward movement of containerized cargo. Its strategic role in the supply chain is enabled by the following core operational pillars:

| Function | Description |

|---|---|

| Rail Connectivity | Linking inland depots with seaports through rail infrastructure to move containers efficiently over long distances |

| Customs Clearance | Handling bonded cargo, EDI messaging (CUSCAR), inspection reporting, and real-time integration with government customs systems |

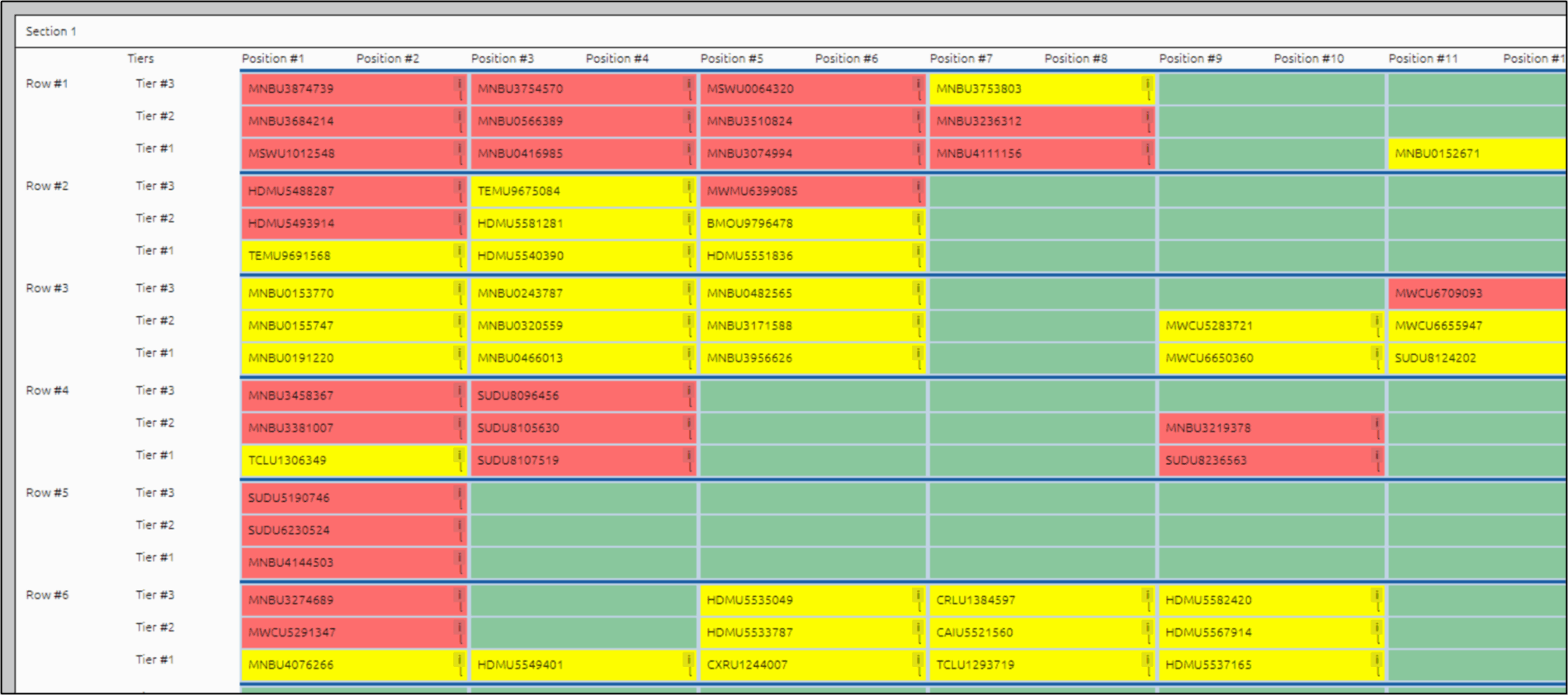

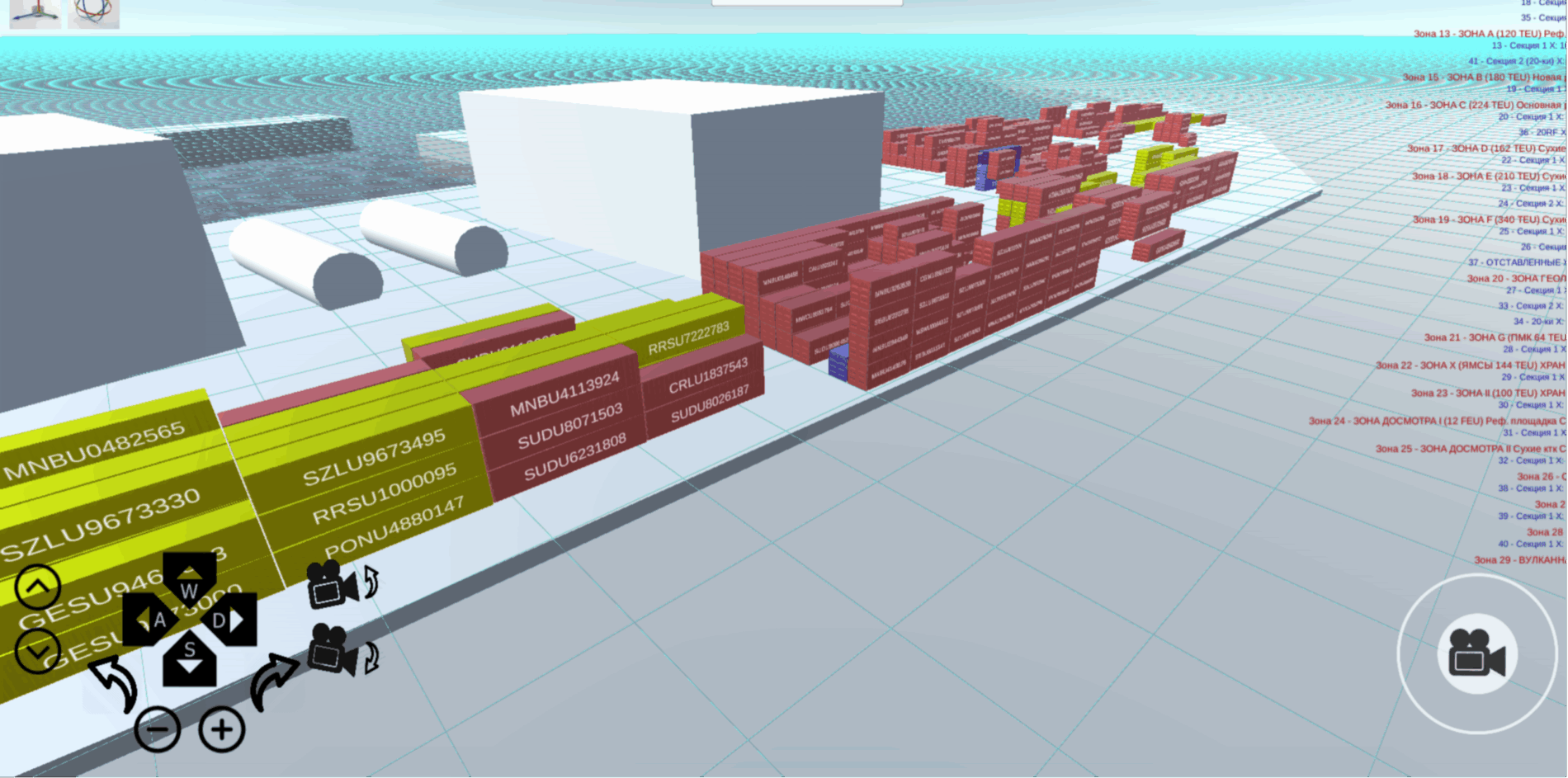

| Yard Management | Allocating slots, tracking aging containers, visual stacking maps, and reducing internal moves |

Core Features of ICD Software

| Feature | Purpose | Benefit |

|---|---|---|

| Gate-In / Gate-Out Automation | Automated vehicle entry/exit processing, CODECO message generation | Reduced truck queue time and improved security |

| Yard Visualization | Graphical container position mapping with filters and occupancy levels | Faster container location, optimized stacking |

| Rail Slot Scheduling | Coordination of train arrivals, container loading/unloading plan | Better synchronization with railway operators |

| Repair & Maintenance | Log container damages, assign technicians, track repair status | Improved safety, transparent invoicing |

Benefits of ICD Software

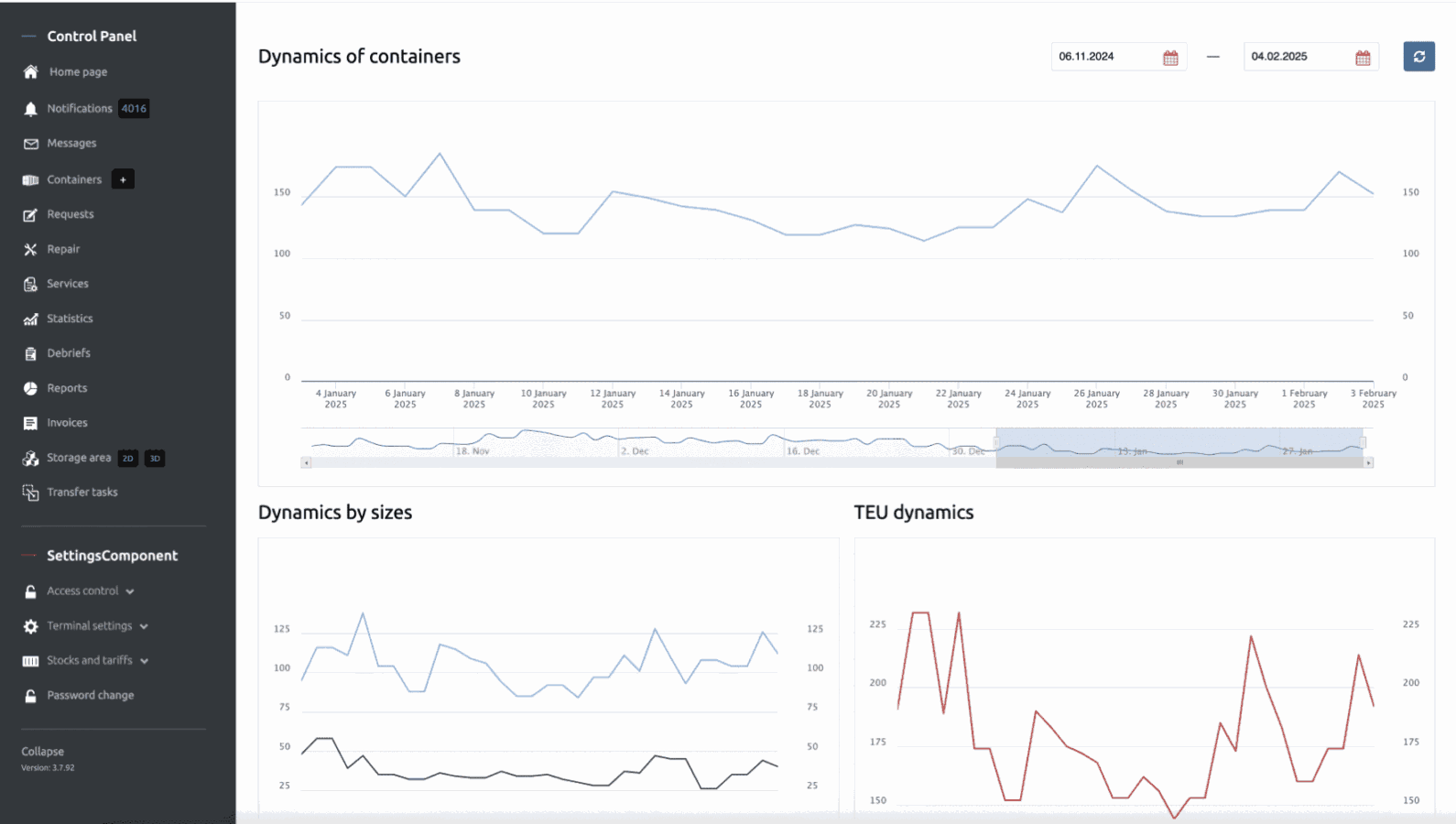

Deploying a well-designed Inland Container Depot Software solution brings measurable advantages to dry ports, logistics parks, and intermodal rail terminals. These benefits go beyond simple automation and extend to compliance, scalability, and client service delivery.

- Reduced Dwell Time: Track container aging, trigger alerts for long-staying units, and implement FIFO logic.

- Faster Customs Clearance: Integrate with national customs for real-time inspection and release notifications.

- Increased Billing Accuracy: Automate charge calculation based on container status, duration, and services.

- Enhanced Client Transparency: Offer clients real-time dashboards and container movement history via online portals.

- Operational Scalability: Configure multiple yards, bonded zones, and transport modes without custom development.

Use Cases: ICD Software in Action

| Scenario | Implementation | Result |

|---|---|---|

| Government-Owned Inland Dry Port | Integrated EDI with customs system, implemented bonded zone module | Cut container clearance time by 60%, improved audit readiness |

| Private Rail-Linked Depot | Added rail scheduling, synchronized yard planning with rail slots | Increased container handling capacity by 30% |

| Multimodal ICD Hub with 3PL Services | Enabled client portal, repair module, and document scanning | Boosted customer satisfaction and internal processing speed |

Deployment Roadmap for ICD Facilities

Implementing Inland Container Depot Software requires clear phases to ensure process alignment, staff readiness, and uninterrupted operations.

| Phase | Duration | Main Objective |

|---|---|---|

| Analysis & Mapping | 1 week | Identify workflows, define data requirements, and set goals |

| Configuration | 2–3 weeks | Set up users, tariff rules, yard layout, and EDI endpoints |

| Data Migration | Up to 1 week | Import container inventory, customer accounts, and transactions |

| Training | 5 days | Simulated workflows and role-specific sessions |

| Go-Live & Monitoring | 2–3 days | Launch system with full operations and live support |

Conclusion: A Digital Backbone for Inland Terminals

As container logistics evolve and cargo volumes shift inland, investing in reliable Inland Container Depot Software becomes a strategic advantage. From gate to rail to customs, ICD software allows depots to streamline operations, maintain regulatory compliance, and provide a seamless experience for stakeholders.

Schedule a live demo or contact our team today to learn how our cloud-based ICD platform can transform your inland terminal.