What Is Container Yard Management Software?

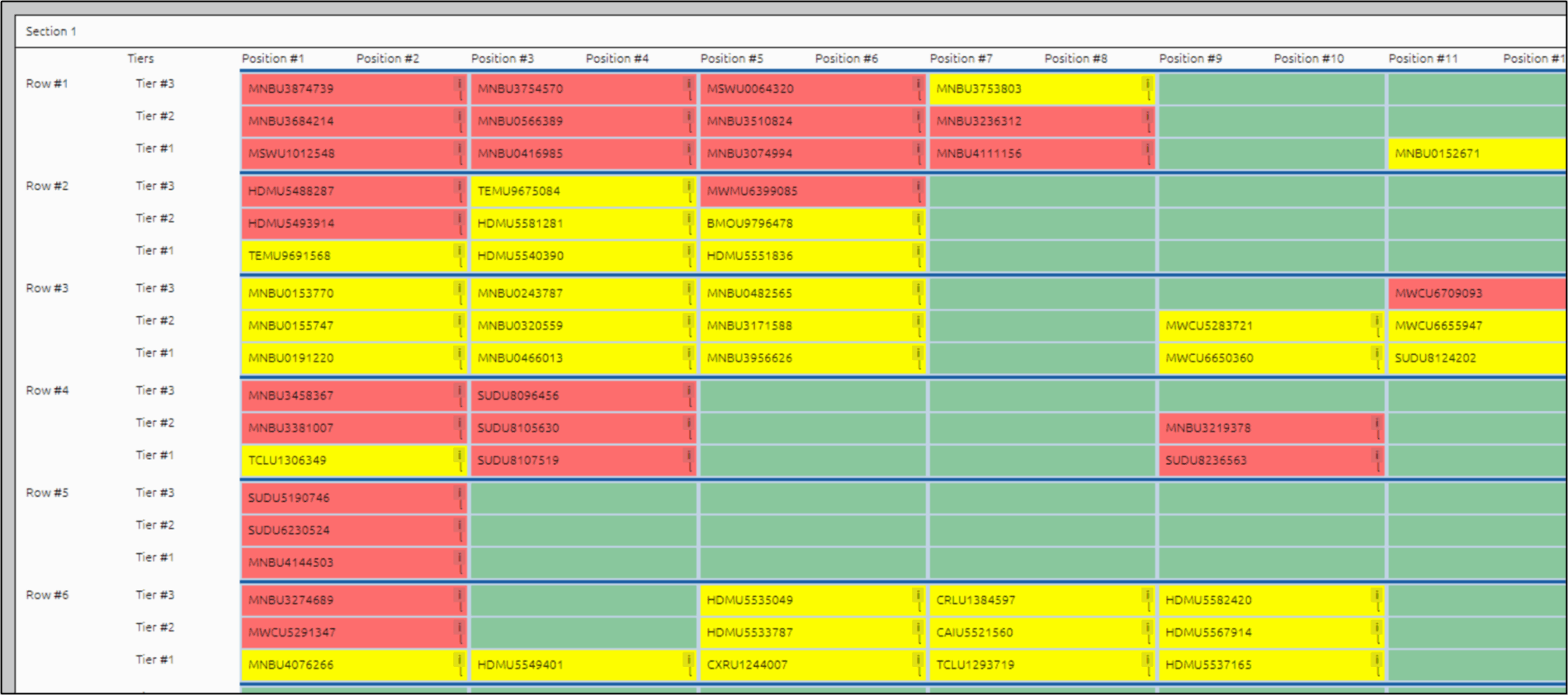

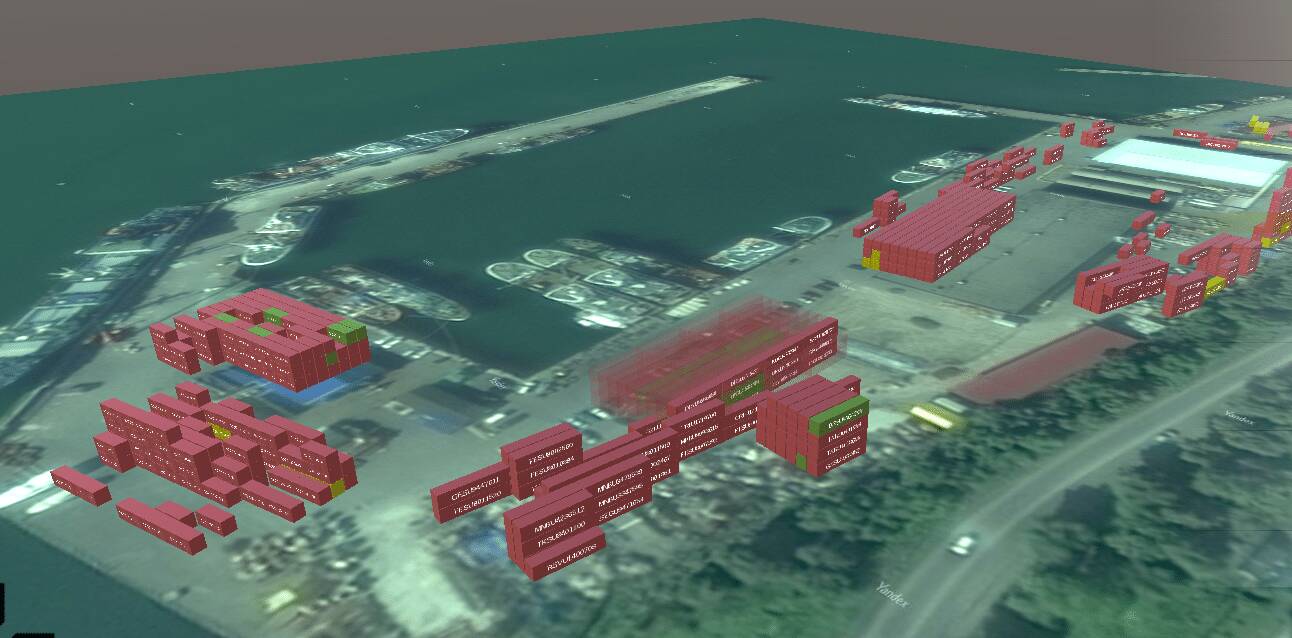

Container Yard Management Software (CYMS) is a specialized module within terminal operating systems designed to control and visualize all container movements and positions within the yard. This software supports both 2D and 3D yard views, provides slot allocation logic, and synchronizes container status across systems such as EDI, gate automation, and equipment dispatch.

Whether the yard is managed manually or semi-automated, CYMS brings visibility, accuracy, and coordination across departments. From tracking TEU flows to assigning RTGs (Rubber-Tyred Gantries) and managing export/import blocks, the software functions as the control tower of the terminal’s physical container space.

Key Challenges in Yard Operations

Without a centralized software system, container yards often suffer from miscommunication, delays, and wasted space. The following table outlines common challenges faced by yard operators:

| Challenge | Description | Impact |

|---|---|---|

| Container Misplacement | Lack of real-time updates on container moves | Delays in retrieval, lost productivity |

| Yard Congestion | Overuse of certain blocks while others remain underutilized | Reduced handling capacity, RTG idling |

| Manual Slot Allocation | Reliance on paper plans and human judgment | Stacking conflicts, unnecessary re-handling |

| No Visual Layout | Yard layout not mapped or available digitally | Errors in yard planning, difficult audits |

These issues can lead to serious operational delays and financial penalties for terminal operators. An advanced yard system solves these problems with logic-driven container handling, alerts, and dynamic views.

Core Features of Yard Management Software

Container Yard Management Software offers a robust set of features specifically tailored to handle the complexity of container stacking, retrieval, and allocation. These tools help terminal operators manage dynamic environments, improve operational accuracy, and streamline all yard processes.

| Feature | Description | Operational Value |

|---|---|---|

| 2D/3D Yard Visualization | Graphical representation of container positions and blocks with filters by status, type, or client | Quick container lookup and real-time overview of yard conditions |

| Automated Slot Allocation | System-suggested stacking locations based on rules, TEU type, stack height, and block availability | Reduces handling effort and container reshuffling |

| Stacking Strategy by Zone | Assign zones by import/export, hazardous, reefer, empty/full containers | Maintains compliance and improves container sorting |

| Equipment Tasking | Dispatch instructions to RTGs, reach stackers, and internal haulers based on yard plan | Synchronizes workforce and machinery, reducing idle time |

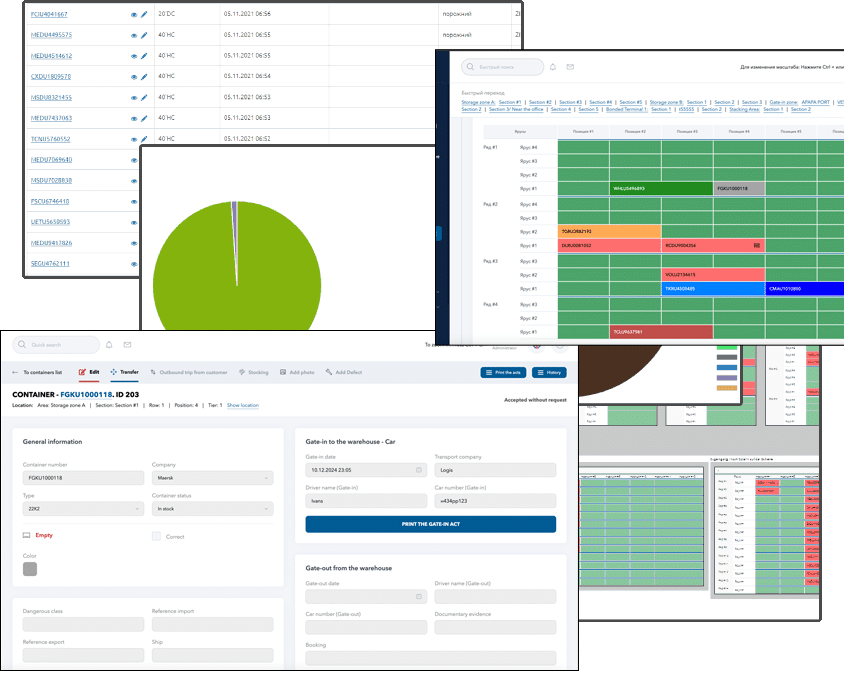

| Container History and Movement Logs | Track each container’s path, including gate-in, stack positions, moves, and gate-out | Improves traceability, supports audits and damage claims |

Yard Planning and Slot Allocation Algorithms

Effective yard planning lies at the heart of terminal efficiency. Yard Management Software uses slotting algorithms and business rules to recommend or auto-assign container locations. These decisions consider stacking height, cargo category, container size, and dwell time.

- Dynamic Slotting: Containers are allocated based on live yard occupancy, reducing dead space and rehandling.

- TEU Mix Awareness: Supports 20ft/40ft slot distinction, twin handling, and block compatibility.

- Yard Heatmaps: Visual tools highlight congestion areas and underused zones for rebalancing.

- Priority Loading Plans: Align stacking with export schedule or customs urgency.

With automated yard planning, terminals can proactively manage congestion, speed up container flow, and lower energy consumption from unnecessary equipment usage.

Real-Time Visibility and Container Tracking

One of the most critical components of yard software is the ability to provide real-time container visibility. With advanced tracking tools, yard operators and clients can locate any container within seconds and monitor its status throughout the terminal lifecycle.

| Tool | Description | Operational Advantage |

|---|---|---|

| Live Yard Dashboard | Interactive interface showing container locations, occupancy rates, and zone filters | Enables proactive decision-making and incident response |

| Mobile Yard Access | Field users can access yard data via tablets or handhelds for stacking or inspections | Improves speed, reduces dependency on control room staff |

| Photo Logging | Attach gate-in/gate-out and damage inspection photos to container records | Ensures accountability, aids in dispute resolution |

| Container Timeline | Chronological log of all moves, events, and statuses for each unit | Enhances traceability and supports audits |

System Integration and Automation

Yard Management Software is most effective when integrated with surrounding systems. Seamless integration ensures synchronized operations and real-time updates across departments. Below are typical integrations that maximize efficiency:

- EDI Gate Messaging: Supports CODECO and COARRI messages for real-time status reporting

- ERP and Financial Systems: Connects yard data with billing, services rendered, and client records

- Gate Systems: Syncs with ANPR, RFID, or manual kiosks for automated gate processing

- Equipment Dispatch: RTG, reachstacker, and internal truck tasking with yard movement logic

- Client Portals & APIs: Enables customer access to container visibility, photos, and service requests

These integrations eliminate redundancy and delays while creating a paperless and connected operational environment.

Benefits of Yard Management Software

Implementing a container yard management system delivers measurable improvements across operational, financial, and customer-facing aspects. With full automation and real-time intelligence, terminals can increase throughput and reduce unnecessary delays.

- Faster Container Handling: Optimized stacking plans and equipment tasking reduce handling time.

- Higher Yard Utilization: Space is dynamically balanced based on container size, category, and priority.

- Reduced Errors: Automated tracking minimizes manual mistakes and container misplacement.

- Better Client Transparency: Live access to container status, documents, and images.

- Data-Driven Insights: Dashboards and reports help management optimize staffing and maintenance.

Whether for a small inland depot or a high-volume terminal, the return on investment for CYMS is significant and visible within weeks of deployment.

Implementation Strategy and Onboarding

Rolling out a container yard management system requires a phased and collaborative approach. Below is a typical roadmap for successful implementation:

| Phase | Activity | Outcome |

|---|---|---|

| Phase 1: Assessment | Map current processes, yard layout, and container flow | Custom system architecture plan |

| Phase 2: Configuration | Set up yard zones, container types, stacking rules, user roles | System tailored to operational logic |

| Phase 3: Training | Conduct staff sessions, simulations, and role-based testing | Workforce readiness and reduced learning curve |

| Phase 4: Go Live | System activated for daily operations with support | Full transition with minimal disruption |

Continuous updates and support ensure the system evolves with terminal needs.

Request a Demo or Start Today

Whether you’re looking to replace paper-based processes or upgrade an outdated yard system, our container yard management software offers the right blend of performance, customization, and usability.

- Try our cloud-based terminal platform in demo mode

- See real-time yard planning and tracking in action

- Experience how automation can transform your container facility

Book a personalized walkthrough today and discover how to bring full control and visibility to your container yard.